The Corvette C6 manual is a comprehensive guide for owners and enthusiasts‚ covering models from 2005 to 2013. It provides detailed instructions for operation‚ maintenance‚ and troubleshooting‚ ensuring optimal performance and longevity of the vehicle.

1.1 Overview of the Corvette C6

The Chevrolet Corvette C6‚ produced from 2005 to 2013‚ is a sixth-generation model known for its sleek design‚ powerful performance‚ and advanced engineering. It features a lightweight aluminum frame‚ a 6.0L or 6.2L V8 engine‚ and rear-wheel drive; The C6 introduced improvements in handling‚ aerodynamics‚ and technology compared to its predecessors. With its retractable headlights and distinctive styling‚ the C6 remains a popular choice among car enthusiasts‚ balancing elegance and raw power for an unforgettable driving experience.

1.2 Importance of the Owner’s Manual

The owner’s manual is essential for Corvette C6 owners‚ offering detailed insights into vehicle operation‚ maintenance‚ and troubleshooting. It provides guidance on optimizing performance‚ understanding features‚ and ensuring safety. The manual helps owners familiarize themselves with the car’s systems‚ preventing potential damage. Regularly referencing the manual ensures compliance with manufacturer recommendations‚ extending the vehicle’s lifespan and maintaining its value. It serves as a vital resource for both new and experienced drivers‚ promoting confident and informed ownership.

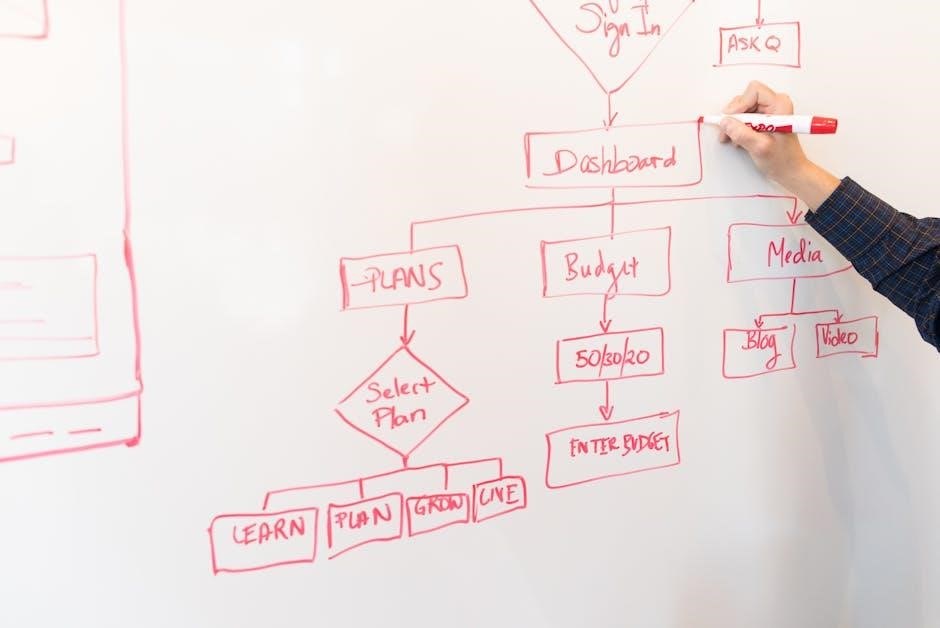

Types of Corvette C6 Manuals

The Corvette C6 manuals include the Owner’s Manual‚ Service Manual‚ and Workshop Manual‚ each providing essential resources for understanding‚ maintaining‚ and repairing the vehicle effectively.

2.1 Owner’s Manual

The Corvette C6 Owner’s Manual provides essential information for drivers‚ covering features‚ operation‚ and maintenance. It includes details on performance‚ safety‚ and troubleshooting‚ ensuring owners understand their vehicle fully. Available as free PDF downloads for models from 2005 to 2013‚ the manual is a vital resource for optimizing the driving experience and caring for the Corvette C6 effectively.

2.2 Service Manual

The Corvette C6 Service Manual offers detailed repair and maintenance instructions‚ ideal for professionals and enthusiasts. Covering models from 2005 to 2013‚ it includes technical specifications‚ diagnostic procedures‚ and repair guidelines. While not available as legal PDFs‚ authorized sources like Helm provide comprehensive guides. This manual is essential for anyone performing advanced repairs or upgrades‚ ensuring work is done safely and correctly‚ adhering to manufacturer standards for optimal vehicle performance and longevity.

2.3 Workshop Manual

The Corvette C6 Workshop Manual is a detailed guide for hands-on maintenance and repairs. It covers models from 2005 to 2013‚ providing step-by-step instructions and diagrams for common procedures. Designed for both professionals and home mechanics‚ it includes information on tools‚ techniques‚ and parts replacement. The manual emphasizes safety and proper techniques‚ ensuring repairs are done efficiently and correctly. It’s an indispensable resource for anyone looking to perform DIY maintenance or more complex modifications‚ keeping the Corvette in prime condition.

Key Features of the Corvette C6

The Corvette C6 boasts a powerful engine‚ aerodynamic design‚ and advanced technology. Its manual highlights features like performance modes‚ handling capabilities‚ and interior comforts‚ enhancing the driving experience.

3.1 Performance Specifications

The Corvette C6 delivers exceptional performance with its 6.0L and 6.2L V8 engines‚ producing up to 430 horsepower. It features a 6-speed manual transmission‚ achieving 0-60 mph in 4.2 seconds. The C6 also boasts impressive handling thanks to its lightweight aluminum frame and advanced suspension system‚ making it a standout in both power and precision driving. These specifications underscore the C6’s reputation as a high-performance sports car‚ blending raw power with refined engineering.

3.2 Design and Engineering

The Corvette C6 features a sleek‚ aerodynamic design with a lightweight aluminum frame‚ enhancing performance and handling. Its advanced suspension system ensures a smooth ride while maintaining precision control. The C6 also incorporates cutting-edge engineering‚ including a robust 6.0L V8 engine and a 6-speed manual transmission. Optional features like a retractable hardtop and performance-oriented designs in special editions‚ such as the Z06‚ further emphasize its commitment to innovation and driver experience‚ making the C6 a blend of style‚ power‚ and technical excellence.

Maintenance and Repair Guidelines

Regular maintenance is crucial for the Corvette C6’s longevity. This section covers routine tasks like oil changes and tire rotations‚ as well as detailed repair procedures. Always use genuine parts to ensure optimal performance and reliability. Follow the guidelines to keep your Corvette in peak condition.

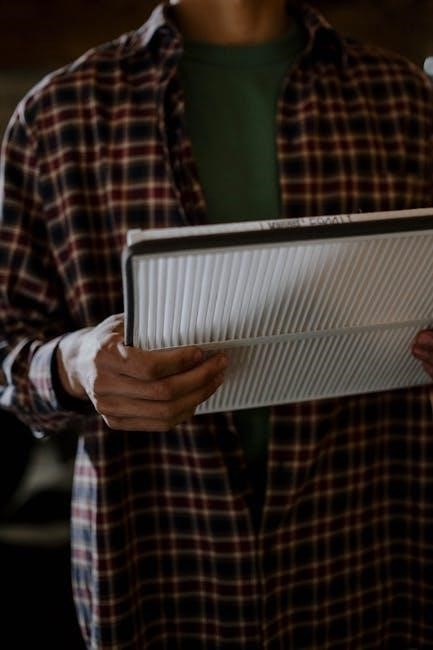

4.1 Routine Maintenance Schedule

The Corvette C6’s routine maintenance schedule ensures optimal performance and longevity. Regular oil changes‚ tire rotations‚ and brake inspections are essential. The manual recommends checking fluid levels‚ air filters‚ and belts at specific intervals. Proper scheduling helps prevent major repairs and maintains the vehicle’s value. Always adhere to the manufacturer’s guidelines for service intervals to ensure your Corvette runs smoothly and efficiently. Timely maintenance is key to preserving its powerful engine and advanced features. Keep track of each service to maintain reliability and performance over time.

4.2 Common Repair Procedures

Common repairs for the Corvette C6 include addressing oil leaks‚ replacing brake pads‚ and fixing electrical issues. The manual details procedures for these tasks‚ ensuring owners can handle them effectively. Regular inspection of the cooling system and suspension is also crucial. For DIY enthusiasts‚ the manual provides step-by-step guides‚ while complex repairs may require professional tools. Always consult the service manual for specific instructions and safety precautions. Proper repair techniques will help maintain the Corvette’s performance and extend its lifespan. Use genuine parts for reliability and to preserve the vehicle’s integrity.

Troubleshooting Tips

The Corvette C6 manual provides troubleshooting tips for common issues such as electrical problems and error codes‚ guiding users through diagnosis and resetting the computer system effectively.

5.1 Diagnosing Common Issues

Diagnosing common issues in the Corvette C6 begins with identifying error codes and symptoms. The manual provides detailed steps to locate and interpret these codes using onboard diagnostics.

Users can troubleshoot electrical system malfunctions‚ sensor failures‚ and performance-related problems. The guide emphasizes checking connections and reviewing the troubleshooting charts for accurate repairs.

5.2 Resetting the Corvette’s Computer System

Resetting the Corvette’s computer system is a straightforward process outlined in the manual. Turn the ignition key to the “ON” position without starting the engine‚ then press and hold the trip odometer button until the system resets. This procedure helps clear error codes and recalibrate settings‚ ensuring optimal performance and accuracy of onboard diagnostics. The manual also provides detailed steps for specific resets‚ such as the electronic throttle control or traction control systems‚ to maintain the vehicle’s advanced features and functionality. Regular resets can prevent minor issues from escalating‚ keeping your Corvette running smoothly.

Advanced Modifications and Upgrades

The Corvette C6 manual highlights advanced modifications and upgrades‚ including performance enhancements and customization options‚ to maximize the vehicle’s potential and personalization for enthusiasts.

6.1 Performance Enhancements

Performance enhancements for the Corvette C6 include engine upgrades‚ such as aftermarket superchargers or high-performance air intakes‚ to boost horsepower and torque. Suspension modifications‚ like adjustable coilovers‚ improve handling and stability. Lightweight wheels and high-grip tires enhance acceleration and cornering capabilities. Additionally‚ exhaust system upgrades can increase power output and deliver a more aggressive sound. These modifications‚ detailed in the manual‚ help owners unlock the full potential of their Corvette‚ ensuring a thrilling driving experience.

6.2 Customization Options

The Corvette C6 manual highlights various customization options to personalize your vehicle. Interior upgrades include premium seat materials‚ color choices‚ and stitching patterns. Exterior modifications involve unique paint finishes‚ body kits‚ and spoilers for a personalized look. Wheels and rims can be customized for style and performance. Additionally‚ technology upgrades‚ such as advanced infotainment systems or driver-assistance features‚ can be integrated. These options allow owners to tailor their Corvette to their preferences‚ enhancing both aesthetics and functionality while maintaining its iconic appeal.

Safety Precautions and Guidelines

Always follow proper lifting techniques and use safety equipment like jack stands to ensure stability. Wear protective gear and work on a level surface for optimal safety.

7.1 Proper Lifting Techniques

Proper lifting techniques are essential for safety and to avoid damage to your Corvette C6. Always use the designated lifting points located near the front and rear wheels. Ensure the vehicle is on a level surface before lifting. Use jack stands for added stability and never rely solely on the jack. Raise the vehicle to a minimum height of 18 inches to ensure clearance for repairs. Always refer to the manual for precise lifting point locations and procedures to maintain safety and prevent damage to the chassis or suspension components.

7.2 Safety Equipment Recommendations

When working on your Corvette C6‚ prioritize safety by using proper equipment. A hydraulic jack and sturdy jack stands are essential for lifting. Use wheel chocks to secure the vehicle and prevent rolling. Wear protective gear such as gloves and safety glasses to avoid injury. Keep a fire extinguisher nearby for emergencies. Ensure the vehicle is on a level surface and the parking brake is engaged. Always refer to the manual for specific safety guidelines tailored to your Corvette C6 to ensure a safe working environment and prevent potential hazards.

Downloading and Accessing Manuals

The Corvette C6 manuals are available as free PDF downloads‚ covering models from 2005 to 2013. These documents provide detailed instructions for maintenance‚ repairs‚ and troubleshooting‚ ensuring easy access to essential information.

8.1 Free PDF Downloads

Free PDF downloads of the Corvette C6 manual are widely available online‚ offering convenient access to detailed information. These manuals cover models from 2005 to 2013‚ providing instructions for maintenance‚ troubleshooting‚ and repairs. Users can download these PDFs from various sources‚ ensuring they have the necessary guidance for optimal vehicle performance. While these downloads are accessible‚ it’s important to verify their authenticity to avoid incomplete or incorrect information. This resource is invaluable for owners seeking to understand and maintain their Corvette C6 effectively.

8.2 Official Sources for Manuals

Official Corvette C6 manuals can be sourced directly from Chevrolet’s website‚ GM’s official resources‚ or authorized dealerships. These manuals are tailored for specific model years‚ ensuring accuracy and relevance. They include detailed instructions for maintenance‚ repairs‚ and troubleshooting‚ along with diagrams for clarity. Official sources guarantee authenticity‚ making them the most reliable choice for owners. Helm Incorporated‚ GM’s approved publisher‚ also provides these manuals‚ covering models from 2005 to 2013. These resources are essential for anyone seeking precise and trustworthy guidance for their Corvette C6.

Legal and Copyright Information

The Corvette C6 manual is protected by copyright laws. All trademarks‚ including CORVETTE and Z06‚ are registered to General Motors Corporation. Reproduction requires permission.

9.1 Intellectual Property Rights

The Corvette C6 manual and its content are protected under copyright laws by General Motors Corporation. All trademarks‚ including CORVETTE‚ Z06‚ and related emblems‚ are owned by GM. Unauthorized reproduction or distribution of the manual or its contents is prohibited and may result in legal action. Proper usage must adhere to intellectual property rights and guidelines set forth by General Motors.

9.2 Proper Usage of Manuals

The Corvette C6 manual is intended for informational and reference purposes only. Users must adhere to copyright laws and refrain from unauthorized reproduction or distribution. Proper usage involves using the manual for personal‚ non-commercial purposes‚ such as maintaining or repairing your vehicle. Always refer to authorized sources‚ like General Motors or licensed publishers‚ for legitimate copies. Sharing or modifying the content without permission is strictly prohibited. Ensure compliance with all legal and safety guidelines when using the manual for repairs or modifications.

The Corvette C6 manual is a vital resource for owners‚ offering comprehensive guides on maintenance‚ troubleshooting‚ and enhancements. It ensures optimal performance and longevity‚ empowering enthusiasts to explore their vehicle’s full potential.

10.1 Final Thoughts on the Corvette C6 Manual

The Corvette C6 manual serves as an essential companion for owners‚ providing detailed insights into maintenance‚ troubleshooting‚ and performance enhancements. It empowers users to maximize their vehicle’s potential while ensuring safety and longevity.

With comprehensive guides covering models from 2005 to 2013‚ the manual remains a vital resource for enthusiasts. Its clarity and depth make it indispensable for both novice and experienced owners‚ fostering a deeper connection with the iconic Corvette C6.

10.2 Encouragement for Further Exploration

Exploring the Corvette C6 manual further will deepen your understanding of its capabilities and customization options. Dive into performance enhancements‚ maintenance tips‚ and troubleshooting guides to optimize your driving experience. Engage with community forums and specialized resources for hands-on advice. Remember‚ continuous learning enhances your connection to this iconic vehicle‚ ensuring it performs at its best for years to come.